The eCommerce Turnaround

Overview

When COVID disrupted our operations and exposed gaps in our eCommerce workflow, I led a full rebuild of our digital commerce ecosystem, from platform selection to inventory integration. The result was a scalable, data-driven channel that doubled revenue annually over the next three years while improving efficiency, dealer trust, and inventory accuracy.

Challenge

Before the rebuild, our eCommerce channel existed mainly to sell maintenance parts. The legacy platform had several critical issues:

- No ERP integration, leading to inaccurate inventory

- Inefficient fulfillment workflows

- Limited reporting and no email segmentation

- Poor product discovery and high customer-service volume

- No email automation for abandoned carts, back-in-stock notifications, or lifecycle communications.

The system was originally chosen because its hosting fees were lower. As online volume grew and worflows became more demanding, the operational bottlenecks and data gaps became increasingly problematic.

My Role

I led the strategy and systems, partnering closely with our eCommerce coordinator, who owned the day-to-day execution, including SKU creation, data, and photography. My responsibilities included:

- Built the business case for switching platforms

- Defined requirements across operations, eCommerce, marketing, and forecasting

- Directed UX and site architecture

- Managed cross-functional partners (e.g. web design, development, data migration)

- Set roadmaps, milestones, and success metrics

- Established the analytics, reporting cadence, and KPIs

Solution:

UX Redesign

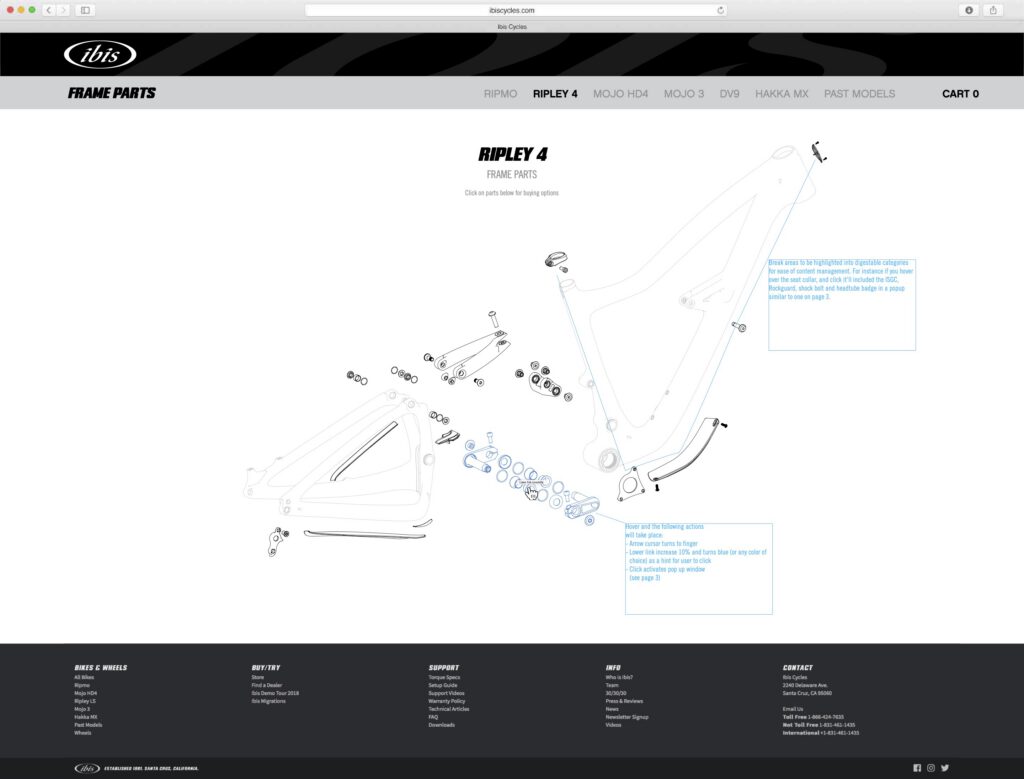

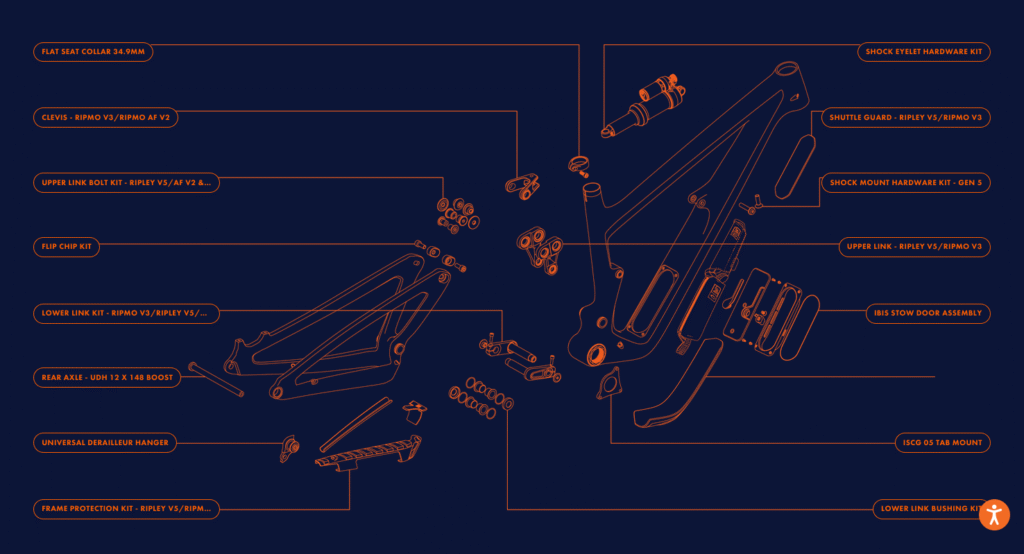

We partnered with Tuan Diep (Assembly One) on UX and Paul Shand (Shand Designs) on development. Key improvements included:

- Interactive exploded diagrams to clarify part fit

- Real-time inventory and low-stock indicators

- Modular homepage, product, and blog templates for flexible merchandising

Data Integration

To connect our eCommerce channel with our ERP, I discovered a connector. This enabled:

- Accurate, near real-time inventory

- Reliable, SKU-level data for purchasing and forecasting

- Eliminated overselling and emergency inventory holds

- Restored dealer trust in our B2B portal

This functionality later powered new dealer-facing inventory tools and our Buy-Online-Pick-Up-In-Store (BOPIS)solution.

Forecasting

I established a recurring reporting rhythm (weekly touchpoints, monthly reviews) that tied demand signals directly to purchasing decisions. By combining SKU velocity, back-in-stock waitlists, seasonality, and direct customer feedback, we created a system that:

- Identified reorder priorities and ideal quantities

- Flagged underperforming SKUs for targeted discounting

- Spotted unmet customer needs and informed new products and accessory development

- Reduced stockouts and stabilized inventory

- Improved purchasing accuracy and working capital efficiency

Launch Integration

I developed a task and timeline framework that we integrated into our project management process, ensuring all e-commerce deliverables were ready for launch. This included:

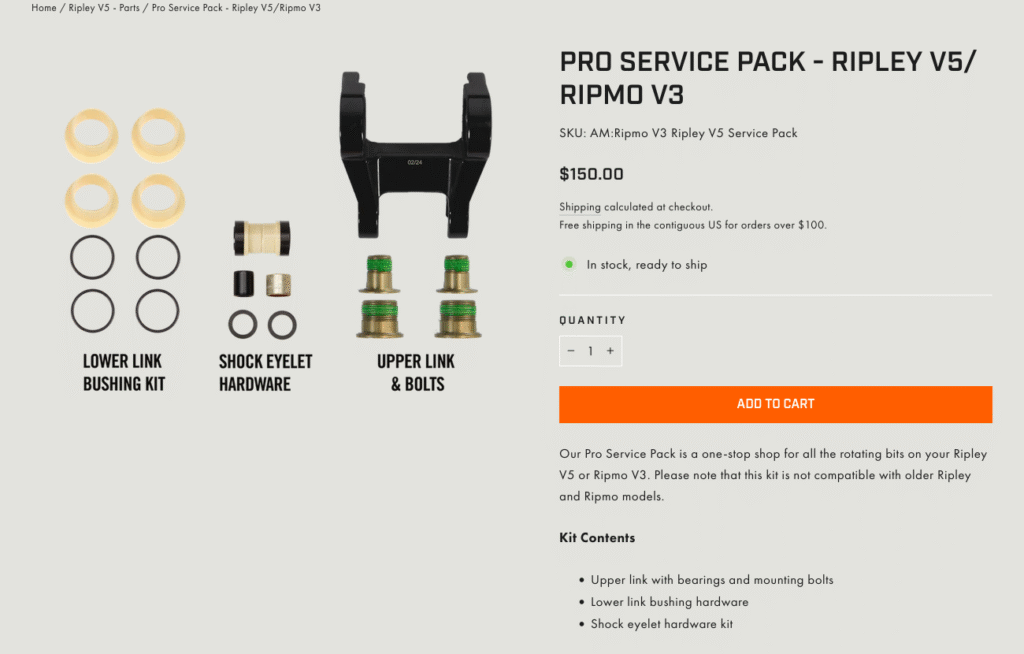

- Oversaw the creation and review of aftermarket BOMs, pricing, margins, photography, descriptions, and listings to ensure accuracy and customer clarity

- Removing obstacles and keeping cross-functional teams on schedule

- Working with engineering early on to develop any required installation tools

This process ensured the timely availability of parts and made it easier for customers to source wear items.

We deployed email tactics like early-access VIP sends and continuous A/B testing to improve conversion, supported by refined layouts designed by Assembly One.

Lifecycle Marketing

After early wins with Shopify’s native email tool, I built the business case to upgrade to Klaviyo for additional segmentation and automation. We implemented:

- Segmented audiences (whales, lapsed purchasers, high-intent browsers)

- Delivery-timed emails with installation instructions that delighted customers and proactively reduce customer service inquiries.

- Expanded automated email and SMS flows (abandoned cart, back in stock)

- Continuous A/B testing and optimization

Klaviyo tripled email-driven revenue in the first month and created compounding lift year over year.

Fulfillment & Inventory Accuracy

As order volume increased, it became clear our manual fulfillment workflow needed a modern, automated solution. We migrated to ShipStation to streamline and scale the process.

- The previous workflow took ~2 minutes per order; migrating to ShipStation cut label and pick-list generation to seconds, delivering a 90% decrease in fulfillment time and saving more than 5 hours per week.

- Working with General Manager Aryeh Benjamin to address shrinkage and inventory discrepancies, we implemented weekly cycle counts by category, rolling into full SKU counts quarterly.

Impact

Rebuilding the digital e-commerce platform transformed it from a minor sales channel (sub-1% of revenue) into one of the company’s fastest-growing revenue sources. The Shopify store ultimately accounted for ~5% of total company revenue and grew large enough to support two full-time employees, compared to one part-time contributor before the migration.

- 2× annual revenue growth for three consecutive years

- Accurate, real-time inventory across B2B and B2C channels

- 3× increase in email-driven revenue in the first month after switching to Klaviyo

- ~90% faster slip/label processing and 5+ hours saved weekly after migrating to ShipStation

- Higher inventory accuracy through weekly cycle counts and quarterly full-SKU audits

- Reduced customer-service volume, especially around fitment and installation

- Improved purchasing accuracy, fewer stockouts, and more reliable forecasting

- Restored dealer trust through consistent, dependable inventory visibility

- A repeatable launch framework that ensured timely parts availability across all channels